PVC Conveyor Belt Green Rubber Grass Conveyor Belt.

Type classification: skirt conveyor belt, special belt, baffle conveyor belt, pattern conveyor belt, turning machine conveyor belt, oil resistance, corrosion resistance, conveyor belt, climbing conveyor belt, timing belt, polyester mesh belt, plus guide belt conveyor belt

Industry Classification: Food Processing Industry, Logistics Airport Industry, Woodworking Industry, Raw Material Industry, Textile/Printing/Paper Industry, Sports and Leisure Industry, Industrial

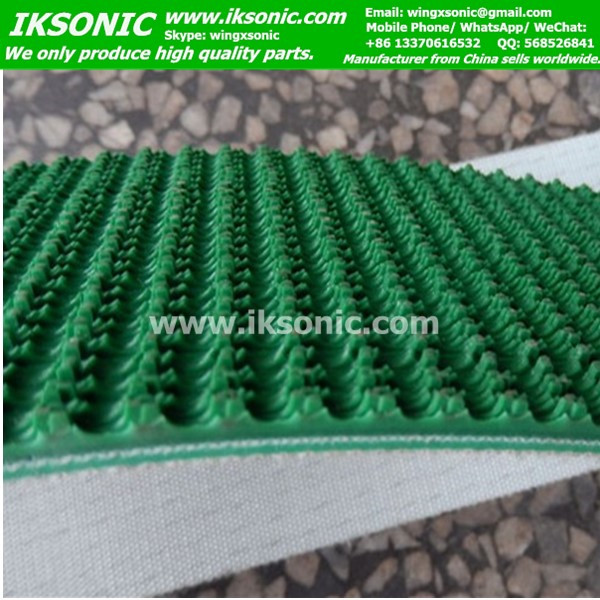

Pattern type: herringbone pattern, I-grain pattern, grass pattern, dot pattern, one-line pattern, crescent pattern, diamond pattern, diamond pattern, cloth pattern, fishbone pattern, straight stripe, golf pattern, crepe pattern, serrated Grain

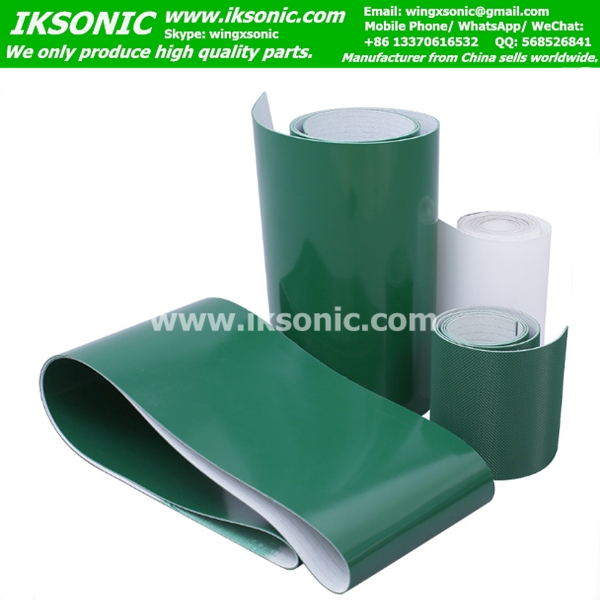

Color Classification :White green transparent black blue orange red dark green gray.

Model: PVC grass pattern belt.

Applicable environment: heat resistance, corrosion resistance, acid resistance, heat resistance, moisture resistance, oil resistance, alkali resistance, wear resistance, burning resistance, cold resistance, non-slip resistance, fire retardant, high temperature resistance.

PVC Conveyor Belt Green Rubber Grass Conveyor Belt

Ordering instructions for the conveyor belt:

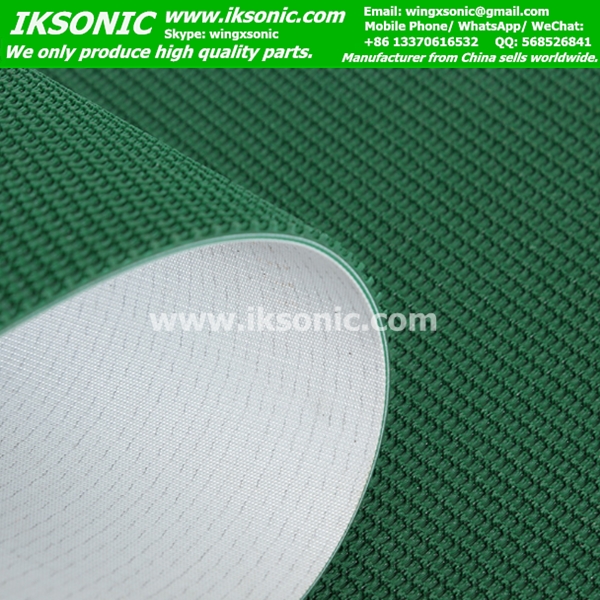

1. Base material: PU (polyurethane), PVC, rubber, silicone and other materials.

2. Baseband thickness: 0.7mm~4.2mm (PU), 1.0~6.0 (pvc), 1.5mm~5mm (silica gel) Rubber: 3.0mm~7.0mm No spot, need to be customized, 7.0mm or more (off the shelf)

3. Color selection: common green, white, black, blue, etc., available for selection.

4. Special processing: guide bars – specifications, processing position, quantity, customized by the customer;

Skirt – specifications, processing position, quantity, customized by the customer;

Baffle / stop – specifications, processing position, quantity, customized by the customer;

Punching – specifications, processing position, quantity, customized by the customer;

Add sponge, foam – specifications, processing position, material, customized by the customer;

5. About connection: opening (not connected); connecting into ring (connecting), available for selection; semi-connected (belt buckle)

6. If the customer is unable to determine the specific data, please contact customer service for assistance. We will propose a solution based on your actual operation.

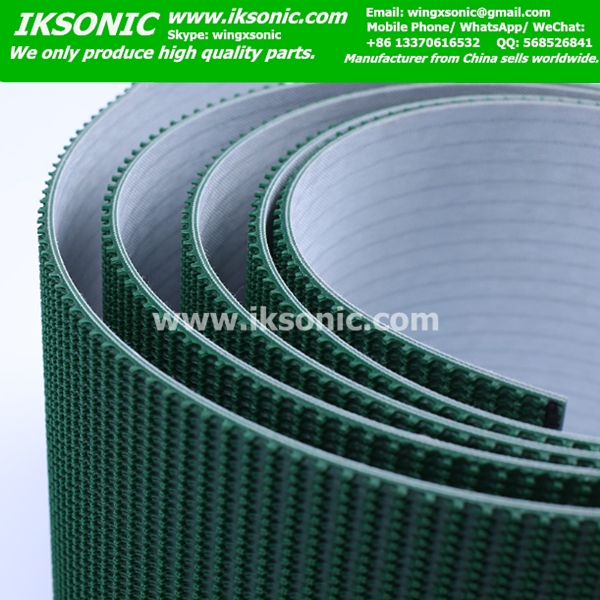

Firstly, The pattern climbing belt line is a type of belt conveyor belt. The climbing belt conveyor is suitable for continuous conveying of goods on the floor or between heights.

Secondly, If the friction of the bottom of the cargo is large enough, a non-slip belt with a pattern on the surface can be used; a large-angle climbing belt conveyor needs to add a baffle and a skirt to the belt; in order to prevent the belt from running off, a strip can be added on the reverse side of the belt.

Thirdly, Pattern climbing belt with optional materials: rubber, PU, PVC (this sample material), Teflon, etc.;

Climbing belts for the industry: light industry, electronics, food, chemicals, wood, machinery and other industries

Application characteristics of the climbing belt:

The conveyor of the belt conveyor is stable, and the material and the conveyor belt have no relative movement, which can avoid damage to the conveyed material. The noise is small, suitable for occasions where the working environment is relatively quiet. The structure is simple and easy to maintain. Low energy consumption and low cost of use.