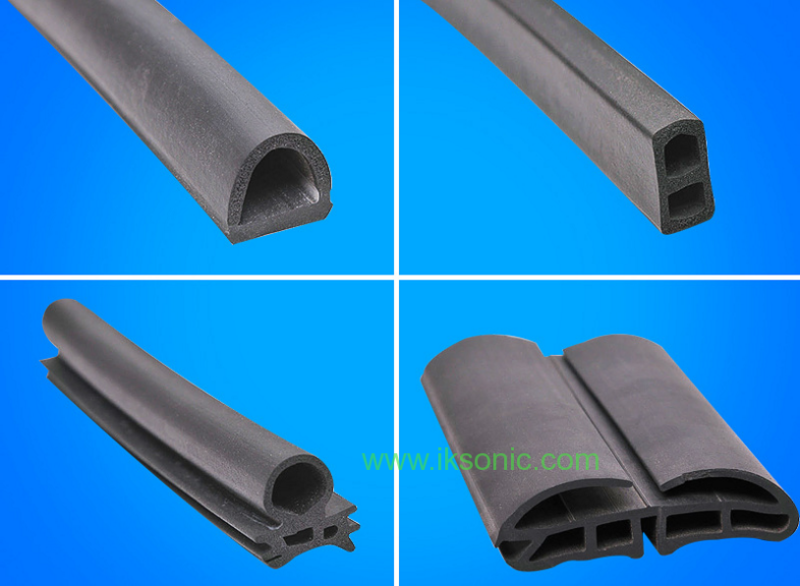

Car window rubber strip

Car window rubber strip used in industry.car window and door.

- Description

- Contact Us

Description

Car window rubber strip of the characteristics and uses

Feature

Automotive seals mainly by having good flexibility and resistance to compression deformation, anti-aging, ozone, chemical action, wide temperature range (-40 ℃ ~ + 120 ℃) EPDM (EPDM) rubber foam and dense composite, contains a unique metal fixture and the tongue-shaped buckle, durable, good for installation.

specification

Temperature range is recommended:

Material EPDM -40 ° F – 248 ° F (-40 ℃ – 120 ℃)

use of Car window rubber strip

Car window rubber strip mainly used in door frames doors, side windows, front and rear windshield, hood and trunk lid, play a waterproof, dust, noise, compartment temperature, shock absorption, decorative role. It can also produce rubber hinge for mounting the doors of passenger baggage.

Unique formulation designed to make EPDM rubber seal has excellent aging resistance, high temperature resistance and chemical resistance properties of chemical drugs, with good elasticity and resistance to deformation, long-term use will not crack or deformation, in – It can maintain its original high sealing performance between 50 degrees to 120 degrees.

Experience strip section design, systems integration design and other aspects to ensure a good waterproof, dust, noise, compartment temperature, damping effect. Seal easy to install, solid and reliable, door switch light activity.

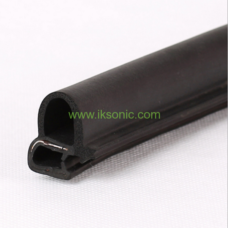

Car window rubber strip production process

1, extrusion

Automotive rubber seals using cold feed extruder molding, extrusion head has single head, complex (double complex and multi-complex) nose and a cut nose. Among them, the microwave curing extruder screw length is generally 16 shear head sulfide extruder screw length greater than 20.

2, vulcanized

Cold feed extruder rubber seal semi-finished continuous vulcanization curing process, curing methods are microwave curing, the shear head sulfide, bath vulcanization and the fluidized bed vulcanization (also known as fluidized bed vulcanization, the heating medium is 0.1 -0.2 mm glass beads, a temperature of 250 ℃), hot air vulcanization (only applies to the silicone rubber sealing strip) and high-speed hot air vulcanization (air flow rate of 120km · h-1, temperature of 400 ℃). Because of the high-speed hot air vulcanization heat slow, high energy consumption, heating equipment (3 times microwave curing heating equipment, five times the shear head sulfide device).

Characteristics of sealing strips 4

1. The modified PVC strips

The price is relatively low, due to the varying quality of the merits, the price is generally between 6,000 yuan 15,000 yuan / ton. Low-end products due to the use of waste, alternative plasticizers and high filler content, to make the tape, poor flexibility, easy to hard, there is the assassination of the nose smell, easy migration to make the frame material yellow, short life. Few low-level price competition in doors and windows are still in use. The high-end PVC strips can meet the standard indicators, life is relatively longer. [2]

Because PVC products containing halogen, stabilizers containing heavy metals, it is not conducive to environmental protection, and therefore foreign countries and domestic Beijing and coastal cities Pat-out or limit the use of PVC strips.

2. The thermoplastic EPDM rubber seal

The sealing strip is developed in recent years on the basis of technology introduced from abroad and domestic independent research and development on a new material, mainly used in car doors and windows sealed, in recent years begun to seal doors and windows for the building. Its outstanding advantages are:

① performance and service life of vulcanized EPDM rubber seal fairly.

② processing vulcanized EPDM seals with respect to energy consumption is low (with PVC equivalent).

③ free of halogens and heavy metals such as lead, plus a few years later recyclable, in line with green building requirements.

④ the proportion of small (only 0.9-0.95) the window rate. Purchase price seems high, low real cost.

Car window rubber strip Features

1) light weight, high strength retractable, non-absorbent products, environmental protection, simple construction, seepage, leakage, good sealing effect.

2) corrosion resistance, aging resistance, high temperature + 80 ℃ ~ -45 ℃ not flowing, no distortion, no embrittlement, long service life.

3) an independent opening bubble structure, a special type of joint appearance of the honeycomb plate holes evenly distributed, do not play with the hair to cement / adhesive sealant closely integrated, adapt to the natural expansion and contraction change, enhance joint seal swell sealing effect.

3. vulcanized EPDM Car window rubber strip

In terms of the sealing elastic persistent than PVC strips greatly enhanced, but because of the need microwave curing line styling, high processing power consumption, typically more than 20 times the PVC processing, the product can not reuse, not environmental protection, not a national advocacy product. In addition, these products share material (1.4 and above) quite (low specific gravity greater vulcanized EPDM seals) and PVC type of windows with PVC strips similar rate, the cost is relatively high, the auto companies is difficult to accept.

click & send an product inquiry to IKSONIC team.

Email: [email protected]

WhatsApp/Mobile/WeChat: +86-13370616532 , +86-15315489052

WeChat: taishanfu

Skype ID: wingxsonic

If you have any questions or products request, please leave message or call us.

Email: [email protected]

WhatsApp/Mobile/WeChat: +86-13370616532 , +86-15315489052

WeChat: taishanfu

Skype ID: wingxsonic